Laser Job Inc. will be exhibiting at SWTest 2025, one of the largest comprehensive shows for Probe Card technologies in America,on june 2-4 in

the Omni La Costa in Carlsbad,CA

Please stop by our booth #305 at Expo Hall. We look forward to seeing you there!

Date: June 2-4,2025

Location: the Omni La Costa Resort & Spa

*For more details, please see the event site SWTest 2025.

Past Events

Customer Benefits

To customers who aim for mass production but find it difficult to install laser processing machines on their own,

we offer outsourcing options suitable for laser processing while eliminating the burden of accommodating engineers and facilities.

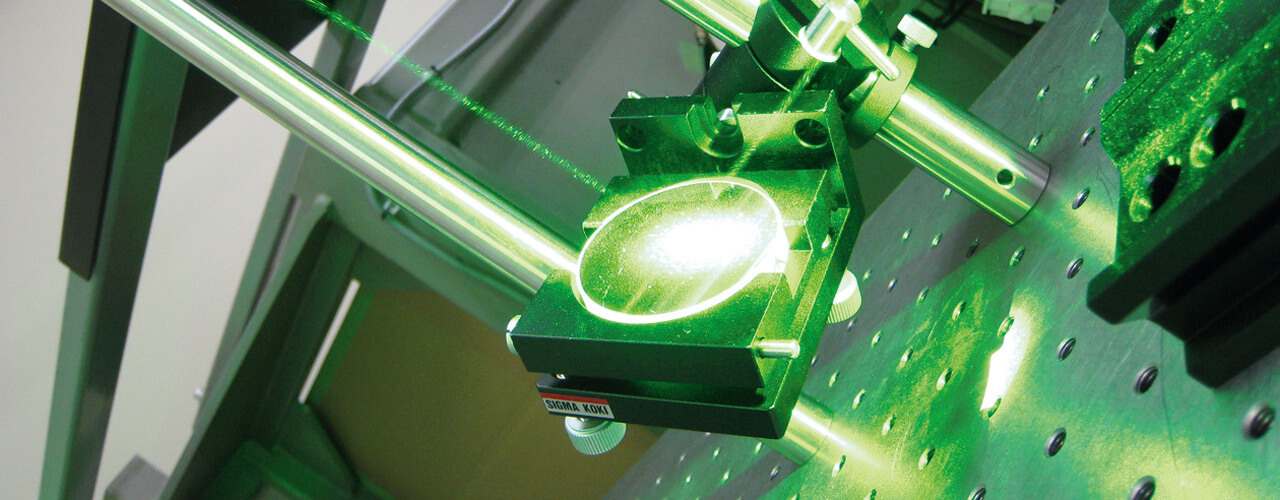

Laser Solution

We are a one-stop shop for laser micro-processing service covering everything from optimal laser processing to prototyping and mass processing.

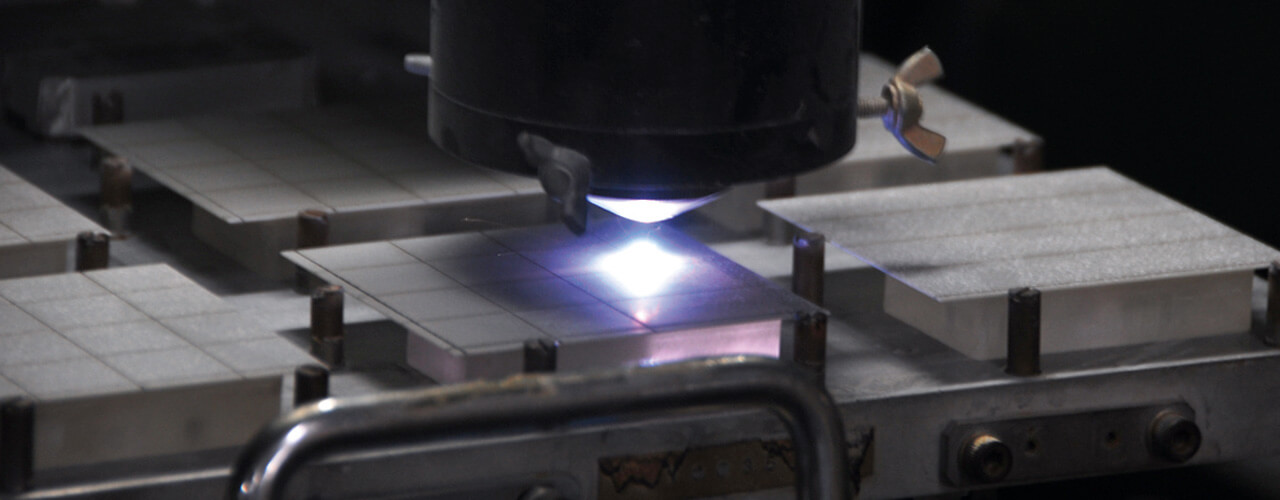

Examples of Laser Processing

Ceramic (Silicon Nitride)

Counterbore

Counterboring process, which was previously only possible using a machine, can now be done using our laser counterboring method. We have achieved a high precision equivalent to the machining process while boasting a faster delivery in comparison to the traditional method.

Ceramic (Silicon Nitride)

Narrow Pitch Machining

Minimizing the taper of laser processing by using our special optical system as well as reducing the pitch has allowed us to also minimize the walls thickness between adjacent holes, and because of that, we are now able to process more micro-holes per area than we used to.

Ceramic (Silicon Nitride)

Square Hole Narrow Angle

To make a square hole most useful, the corners should be as sharp as possible. We used the latest laser oscillator and special optical system to achieve a corner radius that is nearly half that of conventional products.

Ceramic (Silicon Nitride)

High Aspect Ratio Processing

Although high aspect ratio processing is theoretically difficult using a laser processing, we made it possible with a special optical system. For customers who previously needed to layer thin plates, we provide high strength, high precision, and low cost solutions by processing plates to thickness using our high aspect ratio processing.